Formula one car parts are the ultimate benchmark for anyone serious about performance, weight, and aerodynamic precision.

Whether you want track-level grip or head-turning details, understanding how F1 tech converts airflow and materials into real advantages gives your upgrade path a new level of purpose.

We break down the ten most important F1 components and show how their engineering translates to meaningful gains for your own build.

1. Monocoque Survival Cell

Every Formula One car is built around a single, mission-critical structure: the monocoque survival cell. This isn’t just a cockpit; it’s a fortress, performance backbone, and engineering benchmark all in one. If you care about safety, stiffness, and the kind of precise handling that inspires confidence, you need to understand this foundation.

Why F1 Monocoques Set the Standard:

- Carbon fiber skins layered over aluminum honeycomb deliver massive torsional rigidity at a fraction of the weight of steel. Expect a bare cell around 50 kg.

- Designed to absorb and redirect force, the cell acts as a load path for everything—suspension, aero, drivetrain.

- FIA-mandated destructive crash tests (frontal, side, rollover) ensure driver protection is more than a claim. Teams often build backup chassis and rapid-swap systems just to clear racing homologation protocols.

- Integrated Kevlar and fire barriers reinforce the structure inside, not just outside, reflecting world-class attention to detail.

- Engineers use digital records to track carbon fiber ply thickness and orientation for each build. That pedigree matters.

- Real-world insight: F1 teams insert strain gauges and accelerometers directly into the cell to catch invisible damage and optimize design year over year.

The survival cell is proof that ultra-stiffness, carefully routed loads, and crash engineering aren’t just buzzwords if you want heroic handling and bulletproof safety.

What’s in it for you?

- If you’re selecting carbon fiber upgrades, prioritize dry pre-preg parts and autoclavable designs, not decorative “show” carbon. The stiffer, the better—for fitment, stability, and performance.

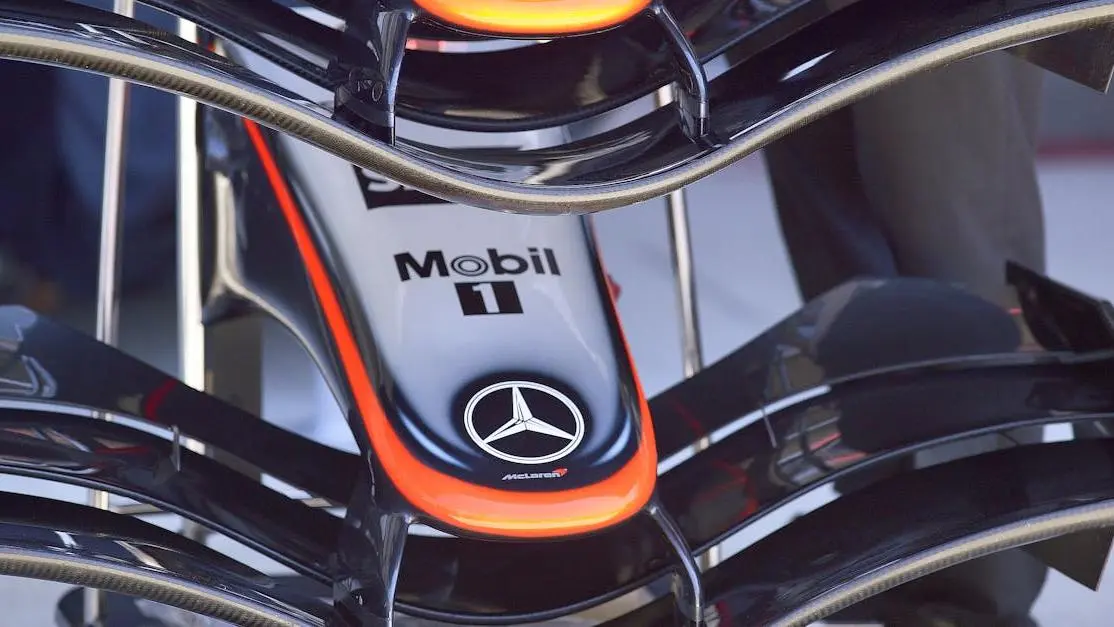

2. Front Wing and Aerodynamic Flow Conditioning

The front wing is the very first thing to hit the air, and what it does with that air defines the rest of your aero. Want sharper turn-in and more predictable grip? Start here.

Modern Front Wing Functionality

- Multi-element carbon construction shapes the pressure field ahead of the car, generating essential front downforce while steering airflow cleanly downstream for cooling and underbody acceleration.

- New load deflection rules mean today’s wings can’t flex or deform under load. Teams fine-tune composite layup angles to pass strict FIA deflection tests at points as specific as 5 mm at set force levels.

Front Wing Impact Checklist

- Multiple elements feed brake ducts, sidepod inlets, and underfloor tunnels—not just the tires.

- Endplates and diveplanes manipulate vortex strength at the edge of legality for tire wake control.

- Correct stiffness is non-negotiable: Flexible wings degrade predictability, shift pressure centers, and destroy lap-to-lap consistency.

If you add a front splitter or aero piece, insist on CAD-verified fitment and robust hardware that holds geometry at speed, just like you’d demand in a top-flight F1 program.

3. Rear Wing, Beam Wing, and DRS

The rear wing doesn’t just cap your aero package; it defines how the car plants itself under heavy acceleration and when DRS opens, it unlocks crucial overtaking potential.

What Makes F1 Rear Wings Different

- The mainplane and beam wing are tuned for massive downforce while stabilizing yaw and maximizing traction at corner exit.

- DRS swaps downforce for top speed in an instant, activating via a driver-controlled servo, and must return shut within 400 ms when deactivated.

- Strict FIA tests limit deflection and flex—skin, hinges, and supports must prove their mettle under specific loads and vacuum-style cup tests.

Key Takeaways for Street Builds

- Prioritize actuator reliability and hinge alignment for any deployable aero part. Inconsistent motion kills predictability.

- Only add rear downforce for high speed if your car can maintain front-to-rear balance, especially if you’re running aero upgrades up front.

The DRS system is proof that precise, robust actuation trumps gimmicks. It’s about usable speed, not an uncontrolled slingshot.

4. Floor, Venturi Tunnels, and Diffuser

Modern F1 performance is all about ground effect—a floor that turns air into pure grip with remarkable efficiency. If you want your upgrades to generate real, measurable downforce, your focus needs to be here.

Floor and Diffuser Fundamentals

- Channeling high-speed airflow under the car creates a low-pressure zone; more pressure difference, more downforce, no drag penalty.

- Edge fences and floor geometry seal in that pressure, feeding diffuser expansion and squeezing every ounce of grip from the surface.

What to Watch Out For

- Flexibility kills performance. Modern F1 floors face relentless FIA deflection tests and strict wear monitoring on plank edges.

- Porpoising—an oscillation from ride height changes—can ruin your day. Controlling pitch and heave through suspension settings is as important as aero design itself.

Consistent downforce comes from a stiff, well-mounted floor—never floppy add-ons or loosely fixed splitters.

Prioritize splitter and undertray mounting to factory datum points, insist on bracket stiffness, and validate with pressure or ride height checks.

5. Hybrid V6 Turbo Power Unit and Energy Recovery

The F1 power unit delivers world-class output at mind-bending efficiency. Every component works together to recover, store, and unleash energy at the perfect moment.

Turbo-Hybrid Power, Simplified

- 1.6L V6 turbo harnesses two electric motors: MGU-K for braking recovery and MGU-H for thermal energy. Each role is tightly managed and electronically balanced.

- Up to 1000 hp on tap, with 120 kW harvested and deployed via MGU-K, and turbo lag erased by MGU-H direct compressor drive.

- Engineers tackle energy storage, heat management, and output balancing with the kind of discipline that road cars are only now beginning to copy.

Applying the Concept

- Smarter energy management means more usable power, more often. Expect durability, not just peak numbers, and configure systems to balance qualifying bursts with race longevity.

6. Suspension Architecture and Setup

It’s not just about sticking big springs up front or going low. Real control comes from true platform discipline.

F1 Suspension Priorities:

- Pushrod or pullrod layouts up front and rear for tight packaging and superior airflow. Placement affects everything, from ride height to shock cooling.

- Anti-dive and anti-squat geometry to keep the car stable under braking or acceleration—a trick you can use to reduce squirm in your street build.

- Third spring or heave elements for platform control on bumpy tracks, not just flat tarmac. Tire contact and aero depend on millimeter-precise response.

For your own build:

- Upgrade subframe bushings and suspension mounts for less flex, especially if you add downforce. Choose spring and damper rates for predictable control, not just ride comfort.

- Skip copycat designs that ignore mounting stiffness or ride height control. Track-proven setups always start with the right spring, damper, and geometry choices—not blind imitation.

In high-performance builds, the goal is clear: maximize tire contact, minimize wasted motion, and support platform control for both mechanical and aero grip.

7. Steering Wheel and Driver Interface

Your steering wheel is more than a turning device. It’s your mission control. In F1, it holds over two dozen switches, toggles, and displays—every adjustment a driver can make on the fly for power, brakes, diff, and more.

When everything you need is right at your fingertips, you can react faster, manage tire wear, and control energy with precision. Each button is placed for speed, with big, positive detents you can trust at 5 Gs, in gloves, and on lap 50.

High-level execution: F1 teams build custom wheels for every driver’s fit and driving style, with redundancy in key systems. No errors, even under fatigue.

Driver Interface, Simplified:

- Big, easy-to-find controls for the moves that count: brake bias, energy deployment, pit limiter, clutch.

- A clear display, color-coded cues, and haptic feedback. Even at speed, the data and decisions flow.

- Simulation and real-world drills build muscle memory so you can nail every switch instinctively.

If you crave total control, your upgrade path should put key adjustments where you can actually use them—in reach, labeled, and with the tactile feel you need to execute on your goals.

8. Tires and Compounds

Tires are everything. They’re your one and only link to the road, and the difference between elite grip and sliding off pace is just a few PSI or degrees.

F1 runs 18-inch tires, with up to five dry compounds and specialized wets. The compounds are color coded for quick pit recognition. Teams spend hours plotting heat cycles, hot pressure targets, and camber values. No guesswork.

Tire Setup Insights:

- Temperature and pressure are king. Teams use thermal cameras and pyrometers so they never run cold or overheat.

- Construction matters. F1’s taller 18-inch sidewalls changed how teams tune suspension—more sidewall, different damping.

- Allocation rules drive strategy. Fewer fresh sets means more adaptation, not just outright speed.

Apply these lessons to your own build with IR guns, quality pressure gauges, and a tire log. Track your temps. Find your sweet spot. Grip is the great equalizer.

9. Nosecone and Front Impact Structure

The nose does double duty in crash safety and aero integrity. In F1, it attaches the front wing, absorbs impacts, and must be swapped in seconds after contact.

A dedicated composite nosecone absorbs and dissipates kinetic energy, meeting strict FIA crash loads. The mounting system is engineered for both strength and rapid changes—every connection point matters when seconds are on the line.

You’ll find sensors for ride height and aero loads embedded in many noses, feeding data instantly to the pit wall. It’s all about preserving chassis integrity and keeping your aerodynamics reliable after an incident.

The best upgrade parts aren’t one-time wonders. They’re designed for easy replacement, true fit, and unbreakable reliability.

If you want to go fast safely, consider how your own upgrades will handle a curb strike or track day mistake. Focus on rapid-mount features and spare parts availability.

10. Halo Driver Protection Device

Introduced for one reason: to save lives. The halo is a shaped titanium bar mounted above the cockpit, and in modern F1 it’s proved its worth, surviving hits from cars, tires, and debris at extreme forces.

At just 7 kg, it handles loads over 12 tonnes. The FIA tests both the device and its mounting. Aerodynamic fairings reduce drag, and the system is integrated into the main chassis structure for maximum strength.

Drivers wince at the aesthetics at first, but the results are irrefutable. The halo is your proof that functional safety can be light, strong, and invisible in routine driving.

If you’re aiming for top-tier safety in your own build, consider real structural upgrades, not just basic bolt-ons. Think about head clearance, load paths, and removal ease.

How These Principles Translate to Your Road Car

F1 is about discipline, details, and tangible results. Why should your upgrades be any different? It’s time to demand more from your parts. Here’s how to get there.

Formula One Principles For Your Build:

- Start with platform control—lock down suspension, ride height, and wheel fitment.

- Use functional carbon: dry pre-preg, autoclave-cured, and with CNC-verified mounting. That’s exactly how we produce ASM Design carbon aero kits.

- Install body parts that change airflow, not just grab eyeballs—splitters, side skirts, and diffusers that function at speed and under pressure.

- Choose ASM Performance valvetronic exhausts when you want low backpressure and the option to tune sound on the fly. This gives you F1-inspired flexibility and response.

- Upgrade to ASM Forged Wheels, cut unsprung weight, and preserve exact offsets. Better grip, faster response, and less stress on your expensive tires.

If you want lap time, confidence, and street style, choose fitment, repeatability, and function above all.

Test, measure, repeat. Tire temps and pressure don’t lie. Verify your gains and avoid myths—just like the best teams in the paddock.

Buyer’s Checklist for Carbon Aero Inspired by Formula One

Not all carbon is created equal. Here’s your rapid rundown for picking parts like a pro:

- Choose dry pre-preg carbon, autoclave-cured, with even weave and UV-protective clearcoat.

- Demand CAD-verified fitment and brackets that use OEM mounting points.

- Look for bodywork with the right aero plan—splitters shaped for real downforce, diffusers that don’t stall.

- Insist on torque specs, install guides, and warranty that shows confidence.

- Check ground clearance before you commit—style is useless if you’re scraping everywhere.

The details matter, always. Ask for validation data, and look for modular repair pieces where possible.

Conclusion

Formula One car parts are a complete system. Every component manages air, heat, load, and energy with ruthless focus.

When you choose upgrades, demand real benefits. Get carbon that fits, splitter and undertray packages that actually work, exhausts that free horsepower, and forged wheels that feel alive at every turn.

If you want the highest standards in carbon aero, intelligent exhaust, and forged wheels, build your platform with ASM Design, ASM Performance, and ASM Forged Wheels.

Let’s push your car’s capabilities further—one focused upgrade at a time.