Carbon Fibre Myths

Carbon fibre has become one of the most desirable materials in the automotive world. You see it everywhere — from Formula 1 to street-tuned builds — and it’s easy to understand why. It looks aggressive, promises weight savings, and often carries a reputation for performance. But how much of what you hear is fact… and how much is hype?

At ASM Tuning, we work with carbon fibre every day. We test it. We design it. We live it. And we’ve heard nearly every myth under the sun from enthusiasts, customers, and even competitors.

So today, we’re busting 7 of the most common carbon fibre myths — and helping you make smarter decisions about your build.

Myth #1: All Carbon Fibre Is the Same

This is hands down the most common misconception in the industry. Not all carbon fibre is created equal — far from it.

The Truth:

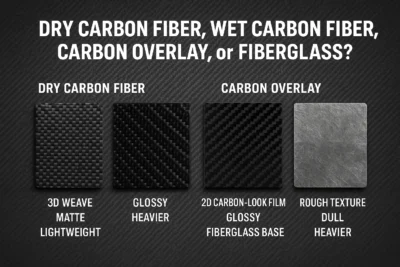

There are multiple types of carbon fibre used in automotive parts, each with different materials, processes, and performance levels:

- Dry Carbon Fiber – The holy grail. Made using pre-preg sheets and autoclave curing. It’s extremely light and strong, often used in motorsports. But it’s also expensive and time-consuming to produce.

- Wet Carbon Fibre – More common in aftermarket parts. Resin is applied during the layup process and cured in molds. It’s heavier than dry carbon but far more affordable.

- Carbon Fibre Overlay – A fiberglass or plastic base covered with a carbon-look sheet. Purely visual, with zero performance gain.

At ASM Tuning, we clearly label and test every product to ensure you know exactly what you’re getting — whether you’re after track-grade performance or street-level style.

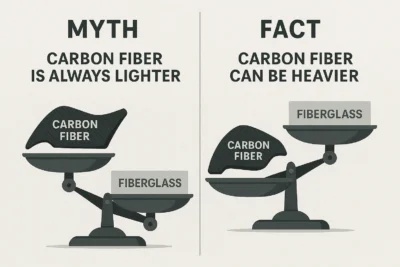

Myth #2: Carbon Fibre Is Always Lighter

People assume anything made from carbon must be ultra-light. While that’s generally true, it’s not a rule.

The Truth:

Poor design cancels out the weight savings.

If a part is made with thick resin layers, or excessive backing material, or even poor molds, it might end up being heavier than fiberglass or aluminium.

Example:

A badly made carbon bonnet might weigh more than a stock aluminium one — especially if it’s a double-skin hood with reinforcements.

Weight reduction depends on:

- Layup quality

- Resin-to-carbon ratio

- Part thickness

- Mounting points and internal support structures

If your goal is true performance, make sure you’re not buying “carbon look” just for show.

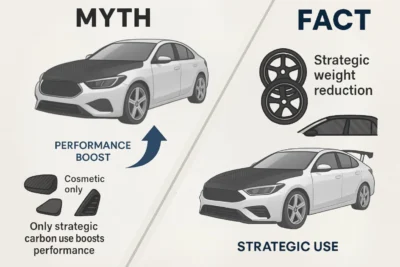

Myth #3: Carbon Fibre Automatically Improves Performance

We get this one a lot. Customers ask us, “If I install this carbon fibre part, will my car be faster?”

The Truth:

Not necessarily. A lighter car can be faster, yes — but only if:

- The weight is removed from the right place (unsprung weight, high-mounted weight, etc.)

- The carbon part contributes to downforce or reduces drag

Installing a carbon fibre rear wing without proper aero balance might actually reduce grip or create instability.

Real performance gain comes when form meets function — like:

- A front splitter that channels airflow correctly

- A vented hood that reduces engine bay pressure

- A carbon diffuser that reduces turbulence under the car

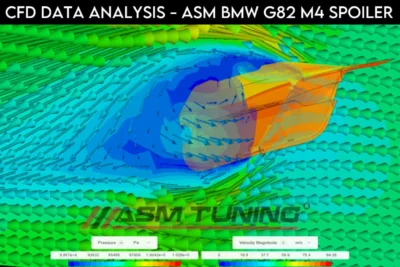

At ASM Tuning we don’t just build for looks — we back our parts with CFD-tested data where applicable, so you know they’re doing more than just sitting pretty.

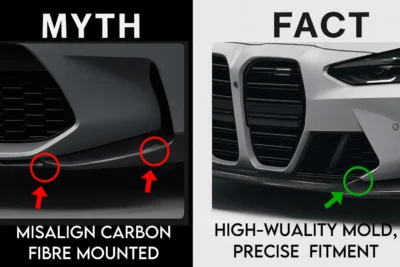

Myth #4: Carbon Fibre Always Fits Perfectly

People assume that because carbon fibre parts are “premium,” they’ll fit flawlessly out of the box.

The Truth:

Fitment depends less on the material and more on the mold quality and factory tolerances.

If a company copies OEM parts using low-resolution scans, or doesn’t quality-check their molds, the carbon part may:

- Warp during curing

- Not align with factory mounts

- Need trimming or drilling

At ASM Tuning, we test fit every mold on real vehicles before production. That’s why our carbon lips, diffusers, and spoilers are known for precision fitment — with no surprises during install.

Myth #5: Carbon Fibre Is Always Expensive

Yes, carbon fibre is a premium material. But in 2025, not all carbon fibre parts will break the bank.

The Truth:

Thanks to improved global manufacturing methods — such as vacuum infusion, CNC mold cutting, and multi-part molds — carbon production has become more efficient.

Budget-friendly carbon fibre exists, but the key is to:

- Avoid fake listings (check for real carbon vs overlay)

- Look for brands that explain the process

- Choose proven suppliers with consistent quality

If a carbon hood is £200 on a marketplace, there’s a reason. But a well-priced £800+ hood from a reputable tuning brand? That’s achievable, and likely to be safe, fit correctly, and look great.

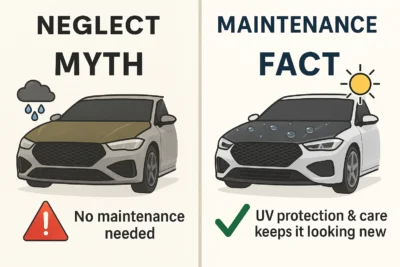

Myth #6: Carbon Fibre Is Maintenance-Free

Here’s another myth that causes long-term damage: many believe carbon parts don’t require any care or protection.

The Truth:

Carbon fibre is strong, but its clear coat and UV protection can wear out like any other exterior surface.

Without maintenance, carbon parts can:

- Fade in the sun

- Yellow over time

- Delaminate from heat or impact

How to maintain carbon fibre:

- Wash regularly with pH-neutral shampoo

- Use a UV-protective ceramic coating or sealant

- Avoid leaving the car in the sun for extended periods

- Re-clearcoat or polish lightly if signs of oxidation appear

When treated right, a high-quality carbon fibre part can look brand new for years.

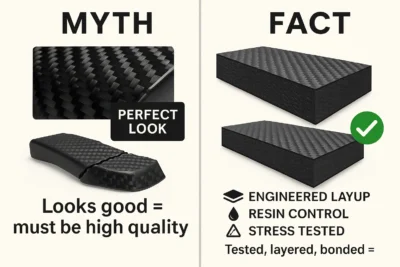

Myth #7: Visible Weave = High Quality

Glossy, uniform weave = great carbon, right? Not always.

The Truth:

Some parts are made to look good but are weak inside.

The visible layer is often cosmetic — and structural strength comes from the internal layers and how they’re cured.

A beautiful weave pattern doesn’t mean:

- The resin was cured properly

- The part has strong core materials

- The manufacturing process was high-end

In fact, some brands polish low-quality carbon overlays to hide defects.

At ASM Tuning, we engineer for performance first, aesthetics second. And luckily, we’re proud to deliver both.

Bonus Myth: Carbon Fibre Is Only for Racers

Some drivers assume carbon upgrades are only for hardcore track builds. That’s not true anymore.

The Truth:

Carbon fibre today is used for:

- Weight reduction

- Visual upgrades

- Aerodynamic performance

- Brand personalization

Whether you’re daily driving your BMW G82 or building a full-time show car, carbon fiber can offer both function and flex — if chosen wisely.

Final Thoughts: Know the Facts Before You Buy

Carbon fibre isn’t just a material — it’s a culture. But like any trend, it’s surrounded by myths, hype, and confusion.

If you’re considering carbon fibre upgrades for your car, keep these tips in mind:

- Know your source — not all sellers are transparent

- Understand your goals — is it for weight, aero, or aesthetics?

- Prioritize fitment — a good-looking part is useless if it doesn’t install properly

- Treat it right — carbon fibre needs maintenance too

At ASM Tuning, we’re committed to educating customers and delivering parts that perform. We test fit, stress test, and often back parts with CFD data. Because in this game, real results always win over rumours.

Recommended ASM Tuning Carbon Fibre Parts

- [ASM BMW G82 Carbon Front Lip (Dry Carbon)]

- [ASM G87 M2 Carbon Rear Diffuser]

- [ASM BMW M Carbon Mirror Covers – Street Style Series]

Frequently Asked Questions About Carbon Fiber

Is all carbon fibre the same?

No. There are different types like dry carbon, wet carbon, and carbon overlay — each with different weight, strength, and cost.

Does carbon fibre always make a car lighter?

Not necessarily. Poorly designed carbon parts can be heavier than fiberglass or aluminium alternatives.

Do carbon fibre parts improve performance?

Only if they reduce weight strategically or improve aerodynamics. Many cosmetic parts have no performance gain.

Do I need to maintain carbon fibre parts?

Yes. Carbon parts require UV protection, regular cleaning, and care to prevent fading or delamination.

How can I spot fake carbon fibre?

Fake carbon is often a fiberglass base with a carbon-look film. Real carbon has distinct weave depth, edge finish, and weight.