Choosing the right high-flow fuel pump can make or break the performance upgrades you’ve worked hard to achieve.

We know how frustrating it is when power gains from your turbo build or carbon fiber aero don’t translate because your fuel system can’t keep up.

That’s why we created this guide—to give you the clarity and confidence you need for your next high-performance step:

- Exactly what choosing the right high-flow fuel pump really means for your build

- How to identify the signs you’ve outgrown your stock fuel system

- Tips to match your fueling upgrade with your performance and styling goals

Understand What a High-Flow Fuel Pump Does and Why It Matters

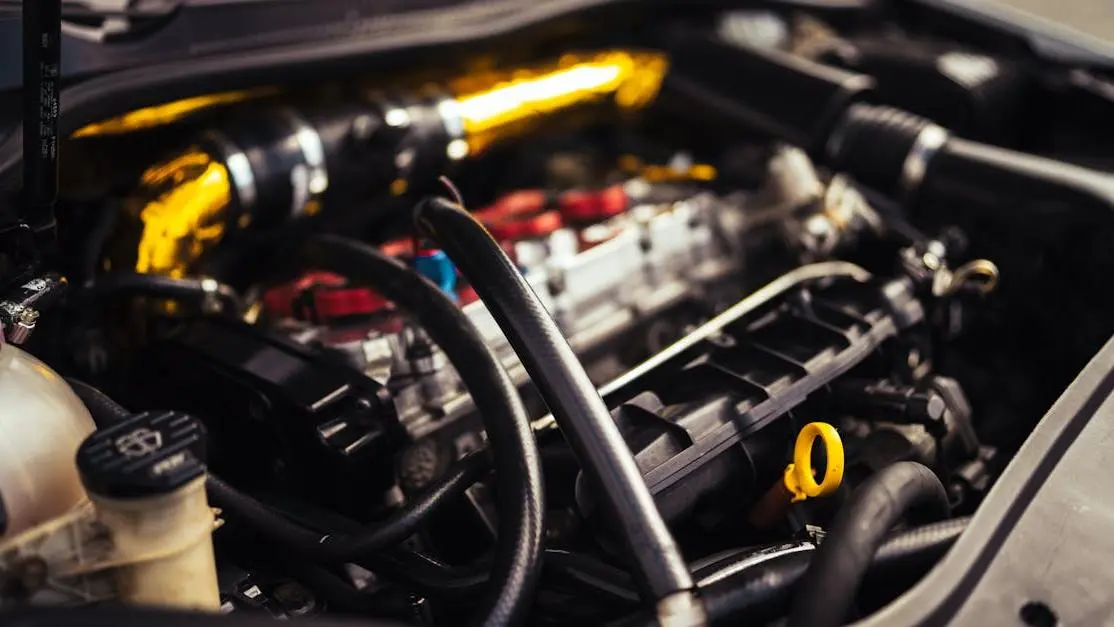

If you want bigger power, sharper throttle, and worry-free reliability with new carbon aero or power mods, your fuel system needs to keep up. A high-flow fuel pump transforms the way your build responds under pressure. It keeps your engine supplied during full-boost pulls or aggressive launches—where a stock pump is outmatched.

- High-flow pumps deliver much more fuel volume at higher pressure, so your engine never runs lean under load.

- Proof: This prevents detonation, high-temp failures, and erratic power in tuned or boosted cars.

- Best-fit: Vital on turbo, supercharged, E85, and high-horsepower builds wanting safer, more consistent output.

- Stock pumps target emissions and economy, not maximum output. They fall short past factory power levels or sustained high RPM.

- Result: No more flat spots, fuel cuts, or tuning headaches as you step up your modification game.

- Installing a matched pump grants your injectors and fuel management the supply needed for stable, repeatable results.

- Example: It brings out the full effect of your upgraded aerodynamic kit with the bite to back up the show.

The right high-flow fuel pump is the bridge between a maxed-out stock drivetrain and the kind of controlled, high-velocity performance your dream build deserves.

We see owners push power with intake, turbo, and carbon upgrades, only to stall progress—for safety and results, plan fueling from the start.

Identify When You Need a High-Flow Fuel Pump for Your Build

Every bold upgrade puts new demands on your factory pump. It’s time to pay attention if you spot issues such as weak top-end power, erratic revving, or persistent fuel cuts at high load.

Key Situations That Call for an Upgrade

- Adding significant boost via turbo or supercharger jumps fuel demand by 20-30% or more, which overwhelms your stock system.

- Ideal for: Any build headed past roughly 350-400 wheel horsepower.

- E85 conversion boosts the volume needed even further.

- Battle with unreliable air-fuel ratios? Tuning challenges often trace back to an overworked pump.

- Sustained track use keeps fuel needs high for long stretches. Street-only cars rarely experience this, but on the circuit, a weak pump risks running lean in critical moments.

Typical Triggers and Performance Benchmarks

Once you switch to larger injectors, aggressive manifold or cam, or aim for record times with a track-focused setup, stock fueling quickly becomes your weakest link. At high elevation, naturally aspirated engines can lean out even sooner due to lower oxygen. Recognize these points in your build and you’ll stay ahead of the curve.

Never let outdated fueling hold your modifications hostage. Track, drag, or show—step up your supply as your ambitions grow.

Know the Different Types of High-Flow Fuel Pumps and How They Work

Before you pick a pump, know your options. Each type serves a specific need based on your power level, fuel choice, and usage.

Types of Pumps and Their Strengths

- In-tank electric is silent, well-cooled, and stable for most modern EFI setups. Top pick for reliable, daily-driven or street-track builds.

- Inline electric increases total flow and helps dual-pump systems, but heat and noise creep up.

- Mechanical/belt-driven gives immense capacity for drag/endurance racers, especially in classic or high-horsepower carb setups.

Pump Technologies and Compatibility

- Gerotor: Great for pressurized EFI, proven reliable. Turbine: very quiet, best for street use.

- Vane: less efficient, now rare except in legacy cars. Brushless: the new performance gold standard, reduces power draw and boosts service life.

If your fuel is E85 or methanol, check for corrosion-resistant internals. Skip this, and failure comes sooner than you think.

Seek function, not just fitment—choose a pump and tech type rated for your ambitions and your fuel.

Learn the Key Criteria for Choosing the Right High-Flow Fuel Pump

Choosing a pump means doing the math, not just chasing big flow numbers. If you don’t calculate the demand for your build, you risk running lean or wasting budget on overkill.

Essential Metrics and Pressure Realities

- Flow rate (LPH or GPH) matters most at your actual operating pressure, not at zero psi.

- BSFC calculations convert target horsepower and fuel type into precise flow needs. Example: For E85, use 0.7-0.8 (not gasoline’s 0.5-0.6).

- Always add a 20% safety margin for future tweaks and to protect your investment.

Fuel System Realities Checklist

- Boost raises fuel pressure at a 1:1 ratio—make sure your pump delivers at that max psi.

- Wiring quality changes real output by up to 20%.

- Bad plumbing or tiny lines become hidden limits even after pump upgrades.

The smartest builders use manufacturer flow-at-pressure charts, not just “max flow” specs. Never guess.

Understand the Impact of Fuel System Supporting Components

You can’t fix undersized lines or tired wiring by bolting in a high-flow pump. The entire system needs attention for real results.

Fuel System Components and Their Influence

- Regulators must control flow without creeping—factory pieces rarely keep up.

- Injectors need the right size, or they’ll max out first.

- Fuel lines should have at least 3/8″ internal diameter for serious builds.

- Electrical upgrades matter: Wire size, relay installation, fuse protection—all crucial or you risk voltage drop and pump burnout.

- Filters must match both flow and fuel type. Wrong filters choke the system and ruin pumps.

Neglecting these pieces turns a premium pump into an expensive band-aid, not a true upgrade.

Every component—regulator, lines, injectors, wiring—must match your pump and power goals for lasting, reliable gains.

Compare the Most Popular High-Flow Fuel Pump Options

It’s easy to get lost in product specs and horsepower claims. We break down the most respected high-flow fuel pumps, real power numbers, and how to avoid being misled.

Top Fuel Pump Picks and Their Ideal Builds

- Walbro 255: Reliable for up to 500hp on gasoline (350hp E85). Perfect for turbo street builds and light track use.

- Walbro 450/525: Go-to for up to 700hp, especially on E85. Used by serious tuners pushing limits with reliability.

- Aeromotive A1000: Supports 1000+ hp. Finds a home in race-prepped muscle cars and big-power builds.

- Bosch 044: Proven in endurance/race setups for high-pressure reliability. Many racers trust this for hard use.

- AEM and DeatschWerks Brushless: Offer improved efficiency, less electrical load, and quiet operation. Ideal for dual-purpose street/track cars needing future-proofing.

- Staged/multi-pump solutions: Engage only during high demand. Keep noise and heat down for daily driving, yet unlock extreme flow when needed. Smart for street machines with serious track weekends.

Noise, amperage draw, and fitment all affect your choice. Street builds benefit from quiet, in-tank or brushless models. Track monsters can tolerate more sound and external pump setups.

Beware: Some pumps claim big LPH at low pressures—always check real-world flow at your required psi before you buy.

Avoid Common Mistakes and Pitfalls When Upgrading to a High-Flow Fuel Pump

Even seasoned builders slip up by rushing choices or skipping steps. Avoid these errors, and you’ll save your engine, time, and money.

Frequent Fuel Pump Upgrade Mistakes

- Undersizing the pump leads to lean-out, detonation, and lost power at peak RPM.

- Oversizing creates excess heat and noise, plus hard starting and vapor lock for street cars.

- Ignoring wiring or voltage drops kills both flow and pump life.

- Using restrictive filters or unchanged lines wastes your investment—bottlenecks kill results.

- Sloppy installation: Rushed mounts, missed O-rings, or poor connections create leaks, surges, and failures.

Check fitment with sending units, use fuel-safe parts, and always pressure-test after install. A well-matched, precisely-installed pump means your system performs when it matters.

The best results come from patience: Confirm numbers, check hardware, and ask experts when you hesitate.

Install and Maintain Your High-Flow Fuel Pump for Longevity and Performance

With your pump chosen, install and care are next. Safety and attention to detail safeguard your upgrade and keep your engine protected.

Fuel Pump Install Steps That Matter Most

- Drain and clean the fuel tank—remove any debris before the new pump.

- Use only new seals, gaskets, and O-rings. Old rubber causes future leaks.

- Upgrade wiring, add a dedicated relay, and fuse correctly.

- Prime and pressure test the system to confirm there are zero leaks or drops.

- Check fuel pressure and AFR with gauges or datalogs before your first hard run.

Ongoing Maintenance and Troubleshooting

- Replace high-flow fuel filters every 10,000–20,000 miles—or sooner if you run ethanol blends.

- Monitor for any pump whine, inconsistent pressure, or sudden AFR changes. These are early warnings of issues.

- Keep records of maintenance and fixes. It saves time diagnosing down the road.

Focused, disciplined care maintains your investment and extends the life of every upgraded component.

Align Your High-Flow Fuel Pump Upgrade with Your Performance & Styling Goals

Every build has a purpose. Your fuel pump should match that vision, whether it’s a weekend track hero, a showstopper with carbon fiber, or a daily rocket you trust.

Fueling upgrades unlocks everything: reliable big-turbo power, smoother mapping, and the confidence to corner harder or sprint longer. You want that musical sound from your carbon diffuser and wing backed up by real, repeatable performance. A fuel system that can’t keep up limits everything else.

We see our customers pairing aggressive appearance with results. Fluent integration across fuel, aero, and electronics now separates top builds from the rest. The right pump isn’t about numbers—it’s about giving you the confidence to chase every last bit of your car’s potential.

Consistent fueling delivers consistent wins—on the street, at the track, and in the looks that turn heads.

Conclusion: Make an Informed Decision and Boost Your Build with the Right Fuel Pump

You now have the tools to size, compare, and choose a high-flow fuel pump that truly fits your goals.

Demand more from your fuel system and match every other upgrade—whether you aim for records, relentless reliability, or a show car that performs as good as it looks.

When you’re ready for guidance or want to discuss your next performance move, reach out to our team. We’re here to support you on the path to a fully realized, head-turning build.