When it comes to upgrading your car with carbon fibre components, the material you choose isn’t just about aesthetics — it affects performance, weight, durability, and cost. Whether you’re building a track machine, a show car, or a performance daily, understanding the differences between dry carbon, and wet carbon will help you make the right decision.

At ASM Tuning, we manufacture and supply all two types of carbon fibre — each suited to different builds and budgets. In this guide, we break down how they’re made, how they perform, and which is best for your project.

What Is Wet Carbon?

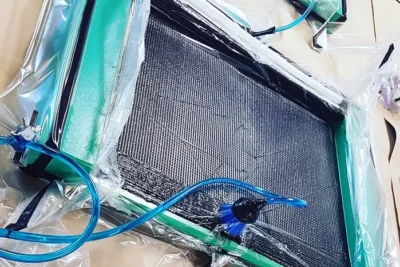

Wet carbon fiber (wet lay-up) is made by saturating carbon fiber fabric with liquid resin in a mold, then curing it (often under a vacuum bag). This process is simpler and cheaper than prepreg, but it leaves more resin in the part.

Wet-laid components typically have a shiny, “wet” look because excess resin creates a glossy coat. However, they are generally heavier and less rigid than dry carbon parts due to the extra resin (and any trapped air)

Key Characteristics:

-

Glossy appearance

-

Heavier than dry carbon due to excess resin

-

More affordable to manufacture

-

Suitable for non-structural aero parts (like diffusers, spoilers, lips)

Wet carbon is ideal for enthusiasts looking for visual upgrades at a reasonable price. It still offers strength and rigidity compared to plastic or fiberglass alternatives — but it’s not the best option where weight savings or extreme performance is the goal.

What Is Dry Carbon?

Dry carbon fiber refers to carbon fiber parts made with a “dry” process – the carbon fabric is pre-impregnated with resin and then cured under heat and pressure (typically in an autoclave).

No liquid resin is added in the mold, so there’s no excess epoxy. This yields a part with minimal resin content and almost no air pockets, making it extremely light (up to 60% lighter than wet carbon) and very strong.

Dry carbon parts come out of the mold with a smooth, gloss finish and a highly consistent weave.

Key Characteristics:

-

Ultra-lightweight – up to 50–60% lighter than wet carbon

-

Stronger – better structural integrity and stiffness

-

Matte or gloss finish

-

Higher cost due to precision manufacturing

-

Used in motorsport, aerospace, and top-tier ASM Tuning Components

Because dry carbon contains only the necessary amount of resin and uses heat/pressure curing, the result is a flawless part with unmatched strength-to-weight ratio. This is why it’s used for critical aero parts, engine bay covers, and racing components.

Which Carbon Fiber Material Should You Choose?

-

Racing/Track Builds: Go with dry carbon (prepreg) – maximum weight savings justify the higher cost.

-

Street Use: Wet carbon fiber is usually sufficient – it’s much affordable and still provides the carbon fiber look with some weight savings.

-

Show Cars: Wet carbon delivers a glossy look at a reasonable price. Choose dry carbon only if you need no-compromise parts and bragging rights.

Dry vs Wet Carbon: Key Differences

| Feature | Dry Carbon | Wet Carbon |

|---|---|---|

| Manufacturing | Vacuum bag + autoclave | Hand-laid with wet resin |

| Weight | Extremely light | Heavier due to excess resin |

| Strength | High structural rigidity | Moderate |

| Finish | Matte or satin (motorsport look) | Glossy, visual appeal |

| Cost | Higher | Budget-friendly |

| Use Case | Track, motorsport, serious builds | Street cars, visual upgrades |

Real-World Applications

At ASM Tuning, we match materials to performance goals:

-

Our dry carbon components are used in extreme builds — like the ASM – BMW G87 M2 Rear Spoiler, which delivers 356.6 N of downforce at 140 km/h verified via CFD.

-

Our prepreg parts offer OEM-quality fitment with the strength needed for aggressive driving — ideal for BMW M cars, Audi RS, and high-performance track builds.

Manufacturing Process: Dry Carbon vs Wet Carbon

Wet carbon fibre uses a wet lay-up process: carbon fabric is placed in a mold and liquid resin is applied over it. The part is then vacuum-bagged and cured without high pressure, which tends to leave excess resin in the finished piece. This method is simple and cost-effective, but the extra resin adds weight and can introduce slight inconsistencies.

In contrast, dry carbon fibre uses pre-preg material – carbon fabric pre-impregnated with resin – which is laid in a mold and cured in an autoclave under high heat and pressure. This yields a part with an optimal resin-to-fibre ratio, no air pockets, and a very consistent structure. Dry carbon’s manufacturing is more complex, producing top-tier quality at a higher cost.

Durability and Maintenance

Dry carbon’s uniform, void-free structure generally makes it more durable under stress (less chance of cracks or delamination forming). Wet carbon’s higher resin content can make it a bit more prone to micro-cracks or yellowing over time, but both types hold up well for years with proper care.

The key is to protect any carbon fibre part from UV exposure (for example, with a UV-resistant clear coat) to prevent sun damage or yellowing. Do that, and both dry and wet carbon components will stay strong and look great long-term.

Finish and Appearance

It’s important to note that “wet” vs “dry” does not refer to surface finish (gloss or matte) – only to how the carbon is made. Either type of carbon fibre can have any finish (glossy, satin, or matte) depending on clear coats and treatment.

Dry carbon typically comes out of the mold with a flat matte texture (no excess resin on top), while wet carbon usually cures to a glossy “wet” look because of the resin coating. However, you can always alter the finish: a dry carbon part can be clear-coated for shine, and a wet carbon part can be given a matte topcoat.

The key is that finish is purely cosmetic – it does not indicate strength or quality of the part.

Why Choose ASM Tuning?

-

✅ Global brand with expertise in carbon manufacturing

-

✅ CFD-tested designs for real aerodynamic benefits

-

✅ High-quality carbon fibre in both dry and wet options

-

✅ UV-coated for longevity

-

✅ Warranty-backed products and expert customer support

Whether you drive a BMW M4, Audi RS3, VW Golf R, or another performance platform — we’ve got carbon fibre components that balance form and function.

Conclusion: Which Carbon Fibre Type Should You Choose?

Both dry and wet carbon fibre have a place in high-performance tuning — and the right choice depends on your goals, budget, and build type.

-

If you’re chasing every gram of weight savings, racing competitively, or want the highest-tier finish and rigidity, dry carbon is the ultimate choice.

-

If you’re building a show car, upgrading a daily driver, or want that aggressive carbon look at a more accessible price, wet carbon offers great value with visual impact.

At ASM Tuning, we offer both options — designed with precision, tested for performance, and backed by real-world data. Whether you’re improving lap times or turning heads on the street, you can trust our carbon fibre components to deliver.

Ready to upgrade your build? Explore our full range of carbon fibre aero.

FAQ Section

What’s the lightest type of carbon fibre?

Dry carbon is the lightest. It’s cured under pressure with no excess resin, making it up to 60% lighter than wet carbon.

Is wet carbon fibre bad?

Not at all — wet carbon still offers great looks and decent strength, especially for visual or non-structural parts. It’s just heavier and slightly less rigid.

Which carbon type is best for racing?

Dry carbon or prepreg carbon are best for racing — they deliver max strength-to-weight ratio, ideal for reducing lap times.

Can you paint or coat carbon fibre?

Yes — ASM Tuning offers both matte and gloss UV-resistant coatings to protect carbon fibre and match your car’s style.

What does “prepreg” mean?

It stands for “pre-impregnated” — the carbon fabric is already soaked with resin, giving perfect consistency in strength and appearance.