Intro: Wheels Are More Than Style – They’re Performance

When it comes to upgrading your car, few modifications offer the perfect balance of form and function like a set of performance wheels. They’re not just visual upgrades — they affect your handling, acceleration, braking, and ride quality.

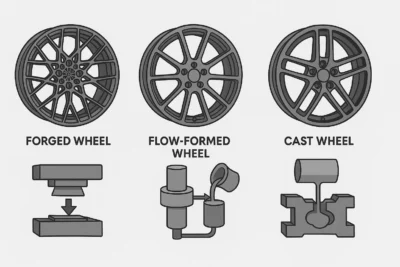

In 2025, car enthusiasts are faced with more choices than ever: forged wheels, flow-formed wheels, cast wheels… all with drastically different prices and promises.

In this guide, we’ll break down the key differences between these wheel types, compare their pros and cons, and help you choose the best setup for your performance goals, budget, and driving style.

1. Understanding the Three Types of Wheels

Cast Wheels are created by pouring molten aluminium into a mold. Once cooled and hardened, the wheel is trimmed and machined. It’s the most cost-effective process but results in more porous metal, making the wheel heavier and less durable under stress.

Flow-Formed Wheels start as cast but undergo additional spinning and pressure application. This reshapes and strengthens the barrel, improving strength-to-weight ratio without the full cost of forging.

Forged Wheels are milled from a single solid aluminium billet. The billet is compressed under extreme pressure to form a dense, lightweight structure. This results in the strongest and lightest wheels on the market.

2. Cast Wheels – Affordable, But at What Cost?

Pros:

– Low initial cost

– Mass availability

– Suitable for light daily use

Cons:

– Heavier and less responsive

– Prone to cracking under hard impacts

– Limited custom sizes, finishes, or offsets

Cast wheels are popular in the OEM and aftermarket space for their affordability, but when it comes to serious driving — spirited road use or track sessions — their limitations start to show.

3. Flow-Formed Wheels – The Middle Ground

Pros:

– Stronger than cast

– Lighter weight, improved handling

– Great for street/track hybrids

Cons:

– Still based on cast blanks

– Strength limited to the barrel

– Fewer high-load rating options

Flow-formed wheels provide a noticeable performance upgrade over cast, offering improved strength and weight without the high cost of full forging. They’re ideal for hot hatches, tuned dailies, and moderate power builds.

4. Forged Wheels – The Enthusiast’s Weapon of Choice

Pros:

– Lightest and strongest construction

– Improved acceleration and cornering

– Fully customizable specs (width, offset, bolt pattern)

– Motorsport-tested durability

Cons:

– Higher upfront cost

– Custom builds may take longer to ship

Forged wheels are used in racing for a reason — the strength and weight savings are unmatched. They reduce unsprung mass, enhance suspension performance, and maintain structural integrity under high load.

5. Why Weight and Strength Matter in Wheels

Reducing weight on your car’s wheels (unsprung, rotational mass) has huge benefits:

– Faster acceleration and shorter braking distances

– More responsive steering and handling

– Better fuel efficiency and tyre wear

Forged wheels can save up to 4-5kg per corner compared to cast. This has a compounding effect on every aspect of driving dynamics, especially at speed or under load.

6. Real-World Performance: On Road and Track

On the road, forged wheels give a noticeably smoother, more planted feel. Every bump is handled better because your suspension isn’t fighting against heavy rotating mass.

On the track, the difference is massive. Reduced wheel weight improves entry and exit speeds, reduces heat build-up on tyres and brakes, and boosts lap consistency.

Flow-formed wheels offer many of these advantages — but not quite the same level of responsiveness or long-term fatigue resistance.

Cast wheels can become a liability under aggressive conditions, increasing your risk of cracking, bending, or sudden failure.

7. Comparing Long-Term Value

While forged wheels cost more upfront, their long-term value often makes them cheaper:

– Better fuel economy from reduced mass

– Fewer replacements over time

– Retain resale value better

– Less tyre and suspension wear

Cast wheels may seem like a deal, but multiple replacements, lower resale, and diminished performance can add up fast.

8. Styling, Customization & Fitment

Our ASM Forged wheels offer total control over:

– Offset

– PCD

– Width and concavity

– Colour finishes (polished, brushed, anodized)

This allows for perfect fitment on lowered cars, wide-body setups, or brake upgrades — things cast and flow-formed options can’t always accommodate.

Your build deserves a wheel that matches your exact needs, not just a close-enough catalogue spec.

9. Who Should Choose Which?

Choose Cast Wheels if:

– You’re on a tight budget

– Your car is stock height and power

– You drive mostly city or suburban roads

Choose Flow-Formed if:

– You want lightweight performance on a budget

– You attend occasional track days

– You’ve upgraded power and suspension but not to extremes

Choose Forged if:

– You demand premium performance

– You track the car or push it regularly

– You care about handling, aesthetics, and long-term value

10. What Makes ASM Forged Wheels Different?

ASM Forged Wheels are designed with one goal: deliver uncompromised performance and aggressive styling to match the cars they’re built for.

Why choose ASM Forged Division:

– Built with aerospace-grade 6061-T6 aluminium

– True motorsport-style forging process

– Designed for BMW M, Audi RS, AMG, and more

– Custom specs available on request

Whether you’re building a daily driver or a dedicated track weapon, our forged wheels give you the strength, lightness, and design edge to do it right.

Explore The ASM Forged Wheels Collection Here

FAQs

Are forged wheels really worth the money?

Yes. The performance gains from weight savings, the durability under extreme conditions, and the long-term value retention make forged wheels a smart investment for serious drivers.

Do forged wheels crack or bend easily?

No. They’re far more resistant to impact damage than cast wheels. While no wheel is indestructible, forged wheels handle potholes, kerbs, and track use far better.

Can forged wheels be used daily?

Absolutely. Many daily drivers use forged wheels for their safety, strength, and enhanced comfort due to better suspension response.

Will forged wheels improve acceleration?

Yes — reducing unsprung, rotational weight improves how quickly your car can accelerate, brake, and change direction.

Final Thoughts: Don’t Compromise on What Matters Most.

Wheels are where performance meets the pavement. Whether you’re after speed, style, or safety — the right wheel choice changes everything.

Cast wheels have a place in budget builds. Flow-formed are a solid compromise. But if you want the best — in feel, form, and function — forged wheels are the clear winner.