Front splitters have become essential for track drivers and style‑minded enthusiasts. Beyond their aggressive look, they deliver real aerodynamic performance by generating downforce and stabilising the front end. This guide explains how splitters work, why carbon fibre is the ideal material, and how ASM Tuning’s splitters can boost your car’s handling.

How a front splitter works

A splitter is a horizontal panel that extends from the lower bumper. As the car moves, it separates airflow: air travelling over the splitter moves faster than the air underneath, creating a low‑pressure region above and a high‑pressure region below.

This difference in pressure pushes the front of the car downward, improving grip and reducing lift. The result is more confident braking and better cornering, especially at higher speeds.

ASM Tuning validates its designs through CFD testing. For example, our dry‑carbon spoiler for the BMW G87 M2 increased downforce by 356.6 N at 140 km/h.

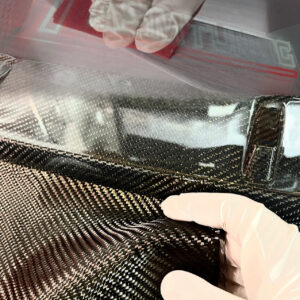

Why carbon fibre?

Splitters are exposed to high aerodynamic loads and occasional impacts, so strength and weight are critical. Carbon fibre provides the same or greater rigidity as steel or aluminium at a fraction of the weight. A lighter nose means less inertia, making the steering more responsive. A performance‑parts guide notes that carbon fibre’s lightweight nature improves acceleration and handling.

Because carbon fibre can be moulded into complex shapes, engineers use it to sculpt aerodynamic profiles that reduce drag and enhance downforce. Its high tensile strength prevents flexing under load, ensuring the splitter maintains its shape at speed.

Carbon fibre also resists heat and corrosion, giving it longevity near hot brakes and road debris. Reducing mass improves fuel efficiency because the engine works less to accelerate the car, and the woven texture and glossy finish give a motorsport‑inspired look.

Design considerations

Size and shape

A splitter’s length determines how much air it captures. Too large and it may scrape on driveways; too small and it won’t produce meaningful downforce. ASM uses computer‑aided design and CFD to refine its products and offers model‑specific options. Reinforced brackets and careful sizing transfer aerodynamic loads into the chassis.

The leading edge should be smooth to reduce turbulence. Many high‑end splitters incorporate small winglets or canards to direct air around the wheels and enhance front‑end grip.

Integration with other aero parts

Aero components work best as a system. Rear diffusers manage airflow exiting the underside of the car, reducing turbulence and drag. Spoilers and GT wings keep the rear planted, balancing the downforce generated at the front.

Without complementary rear parts, a large front splitter can upset the car’s balance. Side skirts further enhance the ground effect by preventing air from spilling underneath. For maximum stability, pair a front splitter with side skirts, a rear diffuser and, if needed, a wing.

Material quality and finish

Carbon fibre comes in different grades. Dry carbon is manufactured using vacuum‑bagging and autoclaves, making it the lightest and strongest option. Prepreg carbon has a consistent resin content and high‑quality finish. Wet‑lay carbon is heavier but more affordable.

For a high‑stress component like a splitter, dry or prepreg carbon is preferable. An automotive carbon part should be coated in a UV‑resistant clear coat to protect against yellowing, and ASM offers gloss, matte or satin finishes.

Installation and fitment

Proper fitment is vital. A splitter designed for one model will not necessarily fit another. Poorly fitting cheap aero parts disturb airflow and can damage bodywork. ASM ensures precise fitment by scanning and CAD‑designing each product to match the factory bumper.

This also means the splitter can be installed using existing hardware without drilling new holes. When installing, take care to align the splitter with the bumper and torque fasteners correctly. If you’re not confident, use a professional fitting service.

Complementary upgrades

Side skirts reduce the flow of air under the car, increasing the effectiveness of your splitter and diffuser. A diffuser accelerates the airflow exiting the underside of the car, reducing drag and adding rear grip. Rear spoilers and GT wings produce downforce that keeps the back end planted.

Without rear downforce, a large splitter may cause the car to feel unstable or oversteer in fast corners.

Choosing your splitter

-

Assess your needs. Daily drivers may want a subtle lip that improves stability without scraping. Track cars benefit from larger splitters with canards.

-

Check legal regulations. In the UK, protruding aero parts must not present sharp edges or extend beyond a certain distance. Consult MOT guidance before fitting.

-

Select quality materials. Choose dry or prepreg carbon for maximum strength. Verify that the part has a UV‑resistant clear coat.

-

Match rear aero. To avoid imbalance, pair the splitter with a diffuser or spoiler. ASM offers matched sets.

-

Choose a reputable manufacturer. ASM Tuning designs each splitter using CAD, tests them with CFD and offers after‑sales support.

Why choose ASM Tuning?

ASM Tuning is a global leader brand in carbon‑fibre aero components. Every splitter is 3D‑scanned and CAD‑modelled, ensuring perfect fitment. Parts are offered in dry or prepreg carbon and finished with UV‑resistant clear coats.

ASM uses CFD and real‑world testing to prove performance, and their products come with after‑sales support and warranty covered.

Conclusion

A carbon‑fibre front splitter is not just a cosmetic upgrade; it’s a functional aero device that creates downforce, improves stability and enhances braking. By manipulating pressure zones around the front bumper, a splitter pushes the tyres into the road. Carbon fibre’s strength and lightness make it the ideal material, and careful design ensures the gains are real.

Pair your splitter with complementary aero parts for a balanced setup, and choose a proven manufacturer like ASM Tuning for parts designed with CFD validation.

Ready to experience the benefits of downforce? Explore ASM Tuning’s range of carbon‑fibre front splitters today and elevate your driving experience.

FAQ – Front Splitters & Carbon Fibre Aero

What does a front splitter do on a car?

A front splitter helps manage airflow by directing high-speed air over the top of the vehicle while reducing the amount going underneath. This increases downforce at the front, improving grip and high-speed stability.

How does a carbon fibre splitter improve performance?

Carbon fibre splitters are incredibly lightweight yet strong. They add downforce without increasing weight, helping your vehicle stay planted at high speed, especially during cornering or braking.

Is a front splitter street legal in the UK or EU?

Generally, yes — as long as the splitter doesn’t extend dangerously beyond the bumper or pose a hazard to pedestrians. ASM Tuning designs its splitters with legal compliance and road safety in mind.

Can I install a carbon fibre splitter myself?

While some splitters are bolt-on, professional installation is recommended for perfect alignment and maximum aerodynamic effect. ASM Tuning offers fitment services and precise installation guides.