What is Carbon Fibre?

What is carbon fibre? In high-performance automotive tuning carbon fibre stands out as the material that has transformed vehicle design. Due to its remarkable durability and light weight together with its modern look carbon fibre has emerged as the top choice in performance enhancements for luxury cars and motorsports.

At ASM Tuning, we specialize in high-quality carbon fibre components that enhance both the performance and appearance of your vehicle. But what exactly is carbon fibre, and why is it so highly sought after?

What Exactly is Carbon Fibre?

Carbon fibre is a high-performance composite material made from thin, strong crystalline filaments of carbon. These fibres are five times stronger than steel yet significantly lighter, making them ideal for automotive, aerospace, and high-tech applications.

Key Properties of Carbon Fibre:

- High strength-to-weight ratio – Stronger than steel but much lighter

- Stiffness – Resists bending and deformation under stress

- Corrosion resistance – Unlike metals, it won’t rust

- Low thermal expansion – Maintains shape under temperature changes

- Aesthetic appeal – Signature woven look for a premium finish

Manufacturers combine carbon fibre with epoxy resins to produce a strong and resilient composite material. The composite material exceeds traditional metals like aluminium and steel in performance across various applications.

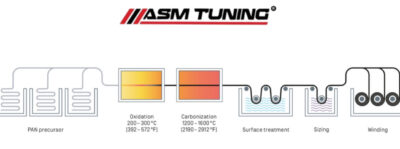

How is Carbon Fibre Made?

Step 1: Precursor Material (PAN or Pitch)

Most carbon fibres start as polyacrylonitrile (PAN), a synthetic polymer. Alternatively, pitch-based carbon fibres are used for specific applications.

Step 2: Oxidation

The PAN fibres are heated in an oxygen-rich environment to stabilize them.

Step 3: Carbonization

The stabilized fibres undergo baking at very high temperatures ranging from 1,000 to 3,000°C inside an inert gas atmosphere. The process eliminates non-carbon atoms to produce pure carbon strands.

Step 4: Surface Treatment & Sizing

Processing of the fibres enhances their adhesive properties with resins and adds a protective surface layer.

Step 5: Weaving & Composite Formation

Manufacturers create rigid composite materials by weaving carbon fibres into sheets with various patterns including plain, twill, or unidirectional and then mixing them with resin.

At ASM Tuning, we use premium aerospace-grade carbon fibre to ensure maximum strength and durability in our automotive parts.

Dry vs Wet Carbon: Know the Difference

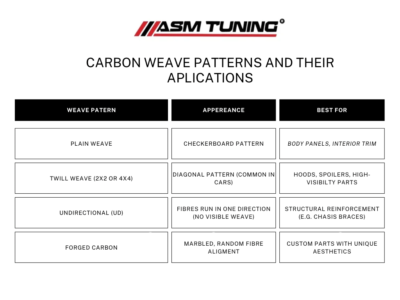

Types of Carbon Fibre Weaves (And Their Uses)

Not all carbon fibre looks or performs the same. The weave pattern affects both aesthetics and mechanical properties.

ASM Tuning offers all these weave options, allowing you to choose based on performance needs or visual preference.

Benefits of Carbon Fibre in Automotive Tuning

Weight Reduction

- Carbon fibre parts can be up to 50% lighter than steel or aluminium.

- Less weight = better acceleration, braking, and fuel efficiency.

Superior Strength & Rigidity

- Enhances structural integrity without adding bulk.

- Critical for high-stress areas like splitters, diffusers, and roll cages.

Corrosion & Fatigue Resistance

- Unlike metal, carbon fibre won’t rust and lasts longer under stress.

Aesthetic Appeal

- The signature weave adds a high-end, motorsport-inspired look

- Available in gloss, matte, or custom finishes at ASM Tuning.

Thermal & Electrical Resistance

- Handles high heat (important for engine bay components).

- Non-conductive, making it safe for electronic housings.

Common Carbon Fibre Upgrades for Cars

At ASM Tuning, we specialize in:

– Exterior Parts: Hoods, spoilers, diffusers, mirror caps

– Interior Trim: Dash panels, steering wheels, shift knobs

– Performance Parts: engine covers, and accessories & more

How to Maintain Carbon Fibre Parts

Maintaining your carbon fibre requires specific care to ensure it continues to look and function as if it’s brand new.

– Use pH-neutral car shampoo to clean regularly while avoiding abrasive cleaners.

– Apply UV-resistant sealant to prevent fading.

– Inspect carbon fibre parts for cracks following any impact because although carbon fibre is strong it can still suffer damage from excessive force.

– Keep carbon fibre parts away from extreme heat exposure such as direct torch flam

What Makes ASM Tuning the Premier Choice for Carbon Fibre Parts?

Carbon fibre is the ultimate material for performance and style, and ASM Tuning delivers the highest-quality carbon components for your vehicle. Whether you’re looking for weight savings, improved aerodynamics, or a race-ready look, we have the expertise and products to transform your build.

Ready to upgrade? Explore our carbon fibre collection or contact us for custom solutions!

FAQ

Is carbon fibre expensive?

- Yes, but the performance benefits and longevity justify the cost for serious enthusiasts

How much weight can carbon fibre actually save

- Typically 40-60% lighter than steel components. For example our carbon hoods save 12-18kg vs OEM steel versions.

Is carbon fibre street legal?

- Yes, 100% legal for all exterior/interior parts. Structural components meet FIA safety standards for track use.

What is the difference between 3K and 12K carbon fibre?

- The number indicated fibre count per strand (3000 vs 12,000 filaments) 3K offers tighter weaves for aesthetics while 12k provides better impact resistance.