The Revolution of Dry Carbon

In the high-performance automotive world, weight is the enemy. Every kilogram removed improves acceleration, handling, fuel efficiency, and the overall driving experience. While carbon fibre has been a staple in motorsport and tuning for years, a new champion has emerged: dry carbon fibre. Also known as pre-preg carbon, this ultra-lightweight material is rapidly becoming the gold standard for serious performance builds.

At ASM Tuning, we’ve embraced dry carbon across our range of aero parts for one simple reason — it delivers unmatched results. In this post, we’ll break down what dry carbon is, how it differs from traditional wet carbon, and why it’s becoming the future of lightweight vehicle development.

What Is Dry Carbon Fibre?

Dry carbon fibre, also known as pre-impregnated carbon fibre or pre-preg, is made by impregnating carbon fabric with a precisely measured amount of epoxy resin during manufacturing. The material is then vacuum-sealed and cured in an autoclave, a high-pressure oven used in aerospace.

Key Features of Dry Carbon:

- Ultra-lightweight (up to 40% lighter than wet carbon)

- Structurally stronger due to perfect resin-to-fibre ratio

- High-temperature resistance

- No air bubbles or imperfections

- Uniform finish and precision fitment

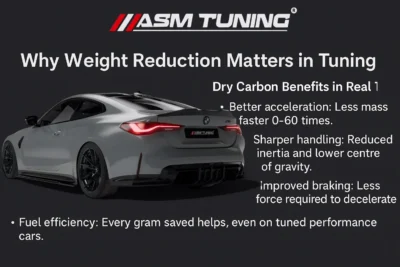

Why Weight Reduction Matters in Tuning

Weight plays a critical role in almost every aspect of a car’s performance. Whether you’re attacking corners, accelerating down straights, or just enjoying spirited drives, shedding kilos is one of the best ways to unlock your car’s potential.

Dry Carbon Benefits in Real Terms:

- Better acceleration: Less mass = faster 0-60 times.

- Sharper handling: Reduced inertia and lower centre of gravity.

- Improved braking: Less force required to decelerate.

- Fuel efficiency: Every gram saved helps, even on tuned performance cars.

How Dry Carbon Is Made: Behind the Craft

At ASM Tuning, we use true autoclave-cured pre-preg carbon fibre to build our components. Here’s a simplified breakdown of how dry carbon parts are created:

- Pre-preg Sheets: Carbon sheets pre-impregnated with resin are cut precisely using CAD templates.

- Lay-Up Process: Sheets are carefully laid into custom molds in multiple layers for directional strength.

- Vacuum Bagging: The mold is sealed in a vacuum bag to remove all air and moisture.

- Autoclave Curing: The sealed mold is heated in an autoclave at controlled pressure and temperature for 1–3 hours.

- Finishing: The cured part is removed, trimmed, and quality-checked for weave alignment and structural perfection.

This process ensures no imperfections, maximum strength, and consistent results across every part.

Why Enthusiasts and Racers Choose Dry Carbon

1. Unmatched Strength-to-Weight Ratio

Dry carbon provides the highest ratio of strength to weight of any composite material available in the tuning market today.

2. Aerospace-Level Manufacturing

Pre-preg carbon is trusted by Formula 1 teams, aerospace companies, and elite tuners. The tolerances are so precise, even structural parts like diffusers and splitters hold up under extreme downforce.

3. Zero Resin Pools or Weak Spots

Wet carbon is often over-saturated with resin, creating heavy spots that compromise integrity. Dry carbon avoids this with exact epoxy distribution.

4. Aesthetic Perfection

You don’t just get performance — dry carbon has impeccable weave uniformity. For builders who value form and function, this is a key reason to choose pre-preg.

Common Dry Carbon Parts That Make a Difference

At ASM Tuning, we offer an extensive dry carbon line-up for platforms like the BMW M3/M4 G80/G82, G87 M2, Audi RS3, and more.

Popular Dry Carbon Upgrades:

- Front splitters (for increased downforce and airflow)

- Side skirts and extensions

- Rear diffusers and valances

- Spoilers and wings

- Carbon mirror caps and interior trims

- Engine bay covers and ducting & more…

Each component is engineered not only to reduce weight but to optimize airflow and aerodynamics — a double win in any build.

Real-World Performance Gains

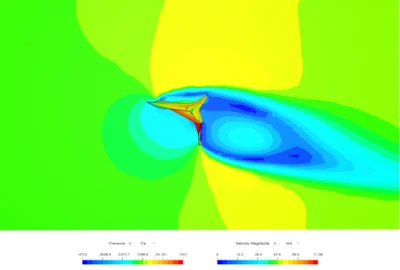

Let’s put things into context with a real example from our own CFD testing:

Case Study: BMW G87 M2 Rear Spoiler – Dry Carbon vs No Spoiler

A CFD test at 140 km/h revealed:

- +356.6 N of downforce increase with ASM’s dry carbon spoiler

- Less drag penalty than heavier plastic or wet carbon designs

- Net downforce increase = better stability at speed

Explore the full CFD test here

Is Dry Carbon Worth the Cost?

Yes — if you’re serious about performance.

Why Dry Carbon Is an Investment:

- It lasts longer due to UV and temperature resistance.

- No risk of structural delamination like cheap wet carbon.

- You get functional aero, not just visual upgrades.

- Resale value is often higher when your car is equipped with genuine pre-preg aero parts.

For true enthusiasts and performance-minded drivers, dry carbon is not a luxury — it’s a necessity.

What’s Next? The Future of Dry Carbon in Automotive Builds

As technology continues to evolve, we’re seeing dry carbon move beyond just motorsport and supercars. With prices becoming more accessible and production more scalable, dry carbon is finding its way into:

- Electric vehicle performance builds (where weight is even more critical)

- Luxury tuner platforms (like AMG, RS, M division cars)

- Track day enthusiasts and club-level racers

- OEM applications (brands like BMW M, Lamborghini, and McLaren already use it extensively)

At ASM Tuning, we’re expanding our dry carbon product lines monthly to meet this demand.

Conclusion: Lightweight Is the Future — and Dry Carbon Leads the Way

Dry carbon fibre is more than a trend. It’s the next evolution of performance and design. For builders, racers, and enthusiasts who refuse to compromise — it’s the only choice.

At ASM Tuning, we craft our parts with passion, precision, and proven aerodynamic data. From the street to the track, our dry carbon components deliver results that you can feel.

FAQs: Dry Carbon Fibre

What’s the difference between dry and forged carbon?

Forged carbon is a mixture of chopped fibres and resin, often pressed into a mold. It’s stronger than wet carbon but doesn’t match dry carbon in structural integrity or weight.

Is dry carbon legal for road use?

Yes — all of ASM Tuning’s dry carbon components are designed for aesthetic and aerodynamic enhancement while remaining safe for road use.

Does dry carbon fade in the sun?

Not ours. All ASM Tuning dry carbon parts are UV-protected with a clear coating to ensure long-lasting performance and visual appeal.

Can I install dry carbon parts myself?

Yes, most parts are bolt-on and include fitment guides. However, we always recommend professional installation for best results.

Do dry carbon parts break easily?

No — dry carbon is stronger than wet carbon. It’s designed to handle real-world forces, including high-speed airflow, vibrations, and temperature changes.

Explore ASM Dry Carbon Fibre Kits

Browse Our Dry Carbon Collection

Contact Us for Fitment Advice or Custom Orders